In our previous blog, How to Embrace Change in Supply Chain with Minimal Impact, we discussed the powerful impact of change on your supply chain 4.0 journey. In this blog, we’ll discuss what to look for in technology vendors when considering a partnership. In addition, we will talk about the importance of having the right level of analytics and metrics that will allow supply chain leaders to control and measure success in the critical areas of the organization.

Exploring the right partnership with a technology vendor and implementer is one of the biggest factors when determining success on the road to industry 4.0 . What you’ll learn is that this is especially true in the supply chain space. Further, the most efficient way to determine if a project was successful is by understanding what critical metrics will be impacted by the process and technology change. Key performance metrics and associated analytics provide the visibility that supply chain processes need to determine both an improvement baseline and target in any process change.

Choosing a Technology Vendor

There are a number of software vendors to choose from a marketplace where new and emerging technologies constantly change the rules of engagement and process excellence. For maximum return on investment, organizations should align with a vendor that not only fulfills defined requirements in the current state, but that also will allow for streamlined processes further down the road as the user base skill stabilizes and improves.

Partnering with a vendor who is constantly addressing emerging technologies, while investing in the latest supply chain process trends directly influenced by best-in-breed companies, will pay dividends for organizations looking to make the journey to supply chain 4.0 as smooth as possible.

As capabilities shift from on-premises to cloud environments, it is also important to understand how the transition will be managed in companies that choose to implement supply chain capabilities in phases, with a corresponding tech stack to support the interfaces of information needed to operate both environments.

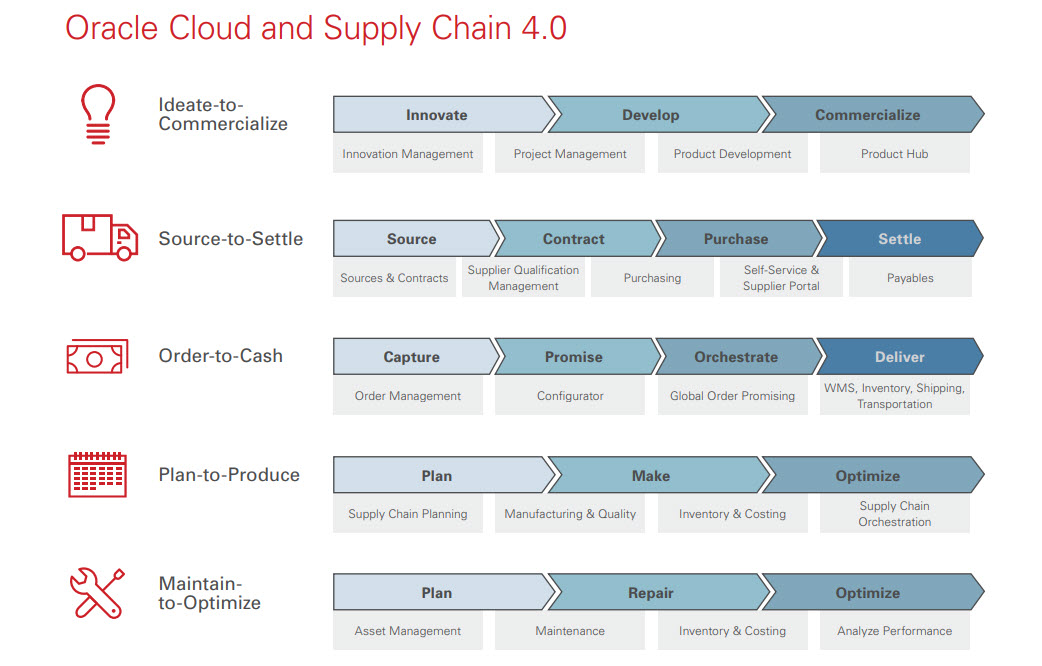

Oracle Supply Chain Management Cloud supports both native and out-of-the-box integration between major business processes such as financials, procurement, manufacturing/distribution, inventory management, logistics, asset maintenance, and field service within a common user interface that takes advantage of emerging technologies and can help enable a successful transition to supply chain 4.0.

Supply Chain Metrics

One of the biggest trends in supply chain 4.0 is the ability to gain real-time insights from an ever-growing set of data that is generated within the different transactions and processes enabled by ERP and other boundary systems.

Defining what process metrics determine success (and gathering the data needed to measure it) becomes of vital importance to organizations seeking to find a quantitative and qualitative way to establish a baseline of excellence. For most supply chain areas, these metrics are agnostic of the toolset being used and should be carefully evaluated and obtained from leading methodologies like Supply Chain Council’s SCOR® model and Balanced Scorecard that represent best in class measurements.

Partner with a professional services organization that can not only help identify the best metrics for signature business processes but also provide the implementation experience to deploy them across the enterprise.

Leveraging a software tool that has some of these metrics already built in is also a good way to jump-start a supply chain transformation project, as it minimizes technical development time and also establishes an initial “true north” for organizations seeking to measure themselves in a more formal way.

Data Visualization, Analytics, and Reporting

At the convergence of people, process, and technology in supply chain 4.0 sits the mountains of data that will support efficient decision making and provide insight into performance. Metrics alone are sometimes not enough to define the success of a given supply chain process, as a result of the complexities that exist in a broad group of customers, suppliers, manufacturers, distributors, and logistics providers.

Supply chain business users are increasingly more demanding of real-time insights and analytics due to the increase in use of mobile apps, efficient web pages, and an overall more technology-centric focus of everyday tasks. This trend must be met with a robust set of reporting capabilities that go above and beyond simple reports of one-dimensional data sets and facts.

Organizations need to support the ever-increasing demands of business users and also make the most of the innovations that come with adopting supply chain 4.0 concepts. To do this, the business needs to put an emphasis on real-time insights that can correlate and organize unstructured data into a cohesive set of dashboards, insights, trend analysis, and prediction algorithms.

To learn more, you can download our entire guide here or below. Otherwise, stay tuned for blog #6 in the coming week on How to Incorporate SCM 4.0 if You’re Not Cloud Ready.