How do Ingredient Changes occur in Oracle OPM? Oracle Process Manufacturing (OPM) jobs have 3 parts; batch jobs, process operations, and recipe. The Recipe is a list of ingredients for the batch job(s). The warehouse compiles the ingredient materials on the recipe to complete the batch job. The quantities cannot be easily revised once they are physically issued to the batch. However, each step of the process has its own process for handling material changes in the recipe. So, what do you do if there are material changes? In this post, we explore potential scenarios where the process manufacturing recipe needs to be revised.

Understanding Ingredient Release in EBS R12 with WMS enabled

There are several types of Manufacturing in Oracle EBS R12. We are going to focus on Batch/Process (OPM) Manufacturing. To better understand process manufacturing, think of making a batch of cookies. If you need additional examples, please see the blog post “Which Manufacturing type your ERP solution is using.”

Planned vs. Ad-Hoc Material requirements

Oracle’s process manufacturing has two processes to add ingredients to a batch; planned and ad-hoc. Planned ingredients are on the recipe. Ingredients issued to the batch “on the fly” are ad-hoc. Usually, this is a result of corrective action to a quality issue.

An example would be adding more flour to the cookie dough because the consistency is not right. Another example would be an on-the-spot substitution. You’ve run out of olive oil and chose to substitute canola oil for the batch.

Changes made before the release of the batch job need to be on the recipe. Ingredient changes after you release a batch job tend to be ad-hoc. A recipe revision is also an option. If this simplest and quickest way to fulfill the material needs is to grab and immediately issued the ingredients to the batch job; then use the ad-hoc method.

The scenarios that we are going to cover are not going to consider Ad-hoc materials.

Outside Processing vs. Make to Order

Outside processing (OSP) is where an external group is working on a piece of the manufacturing process. These processes are not in direct control of the manufacturer. An OSP process is sending out a batch of cookies to be packaged. To be internal, you would have a packaging station in-house. For this post, we are not talking about any material changes to an OSP manufacturing step.

Ingredient changes in Process Picking/OPM Tasks in Oracle WMS

Similar to the Sales Order Fulfillment process, Ingredient picking is a two-step process. Staging the ingredients and issuing the ingredients. In Oracle EBS R12, component picking for the discrete job is a one-step process. Components are picked and issued to the job in one process.

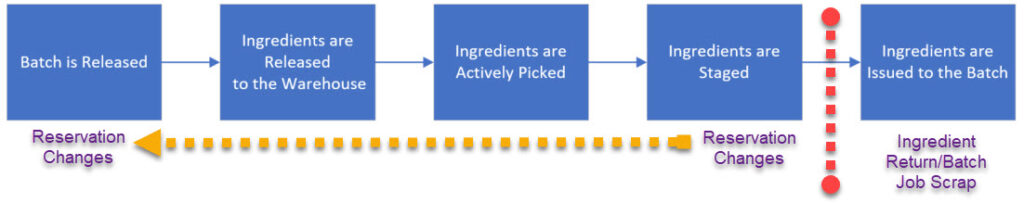

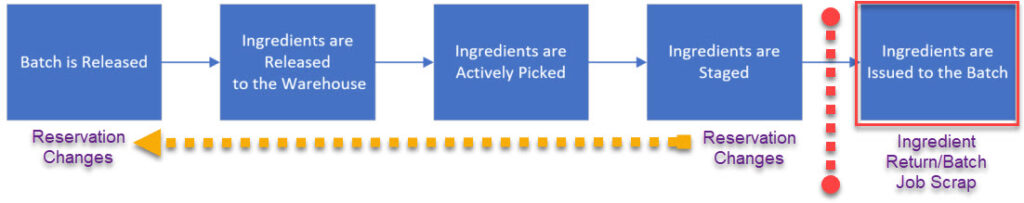

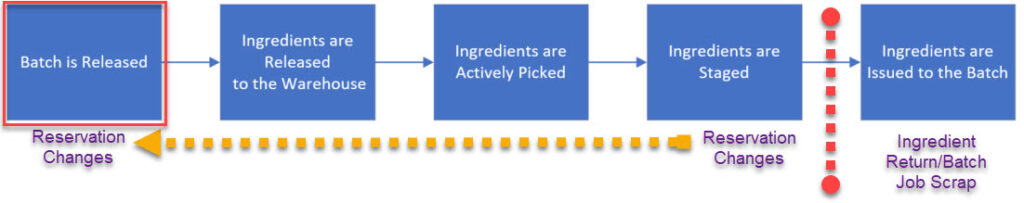

Within this process, there are five phases in the OPM Batch Job lifecycle with Material requirements. They are Job Release, Ingredient request, Ingredient move, Ingredient Issue, and Job completion. The process of making a revision or a cancelation depends on which phase you are in. Ingredient changes can only be made if there are no active move tasks or issued ingredients. So, if you are to look at where you are at. You can then decide which steps are the most efficient way to handle to job.

The Phases of Ingredient needs for an OPM Batch Job are as follows:

Scenarios in OPM & WMS with Material Changes:

- Ingredient changes after the Batch Job(s) are approved (Ingredient Pick Release has not occurred)

- The Warehouse receives the Batch Job and then ingredient changes to the Task/Job occur

- Ingredient changes occur during the Picking of the ingredients for the Batch

- Ingredient changes after materials are staged

- Ingredients have been issued to the Batch when a change occurs

Scenario #1 – Ingredient changes before the batch job is released to the warehouse for picking

Scenario details:

Scenario details:

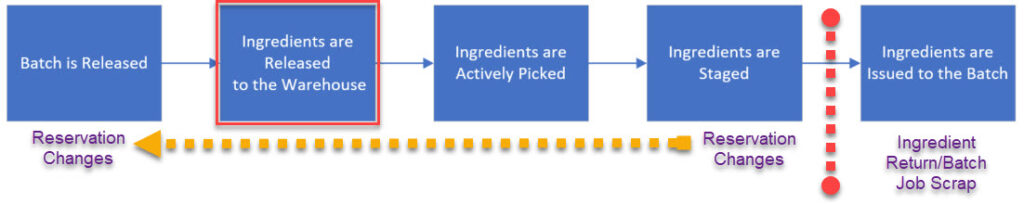

The Process Manufacturing Batch Job is in a “released” status. However, the Warehouse has not received instructions to perform the ingredient picking allocation. Production scheduling requests a change to the Batch Job or cancellation of the batch in its entirety.

Solution Action Plan:

There are no active tasks in the warehouse. Manufacturing operations can easily revise the Recipe. So, the first action is to make sure that the warehouse doesn’t release the batch job for ingredient picking. To do this, Manufacturing operations must inform the Raw Material Warehouse to not release the materials until the Recipe is updated. Once updated, the raw material warehouse can release the job.

Scenario #2 – Warehouse receives the Batch Job and then ingredient changes occur

Scenario details (Assuming a Make-to-Order environment):

In this case, the Batch Job is in a “released” status. The Warehouse has reviewed the ingredients for the job. Warehouse picking tasks exist. In this scenario, the recipe has changed due to an issue discovered with an earlier batch. The ingredient amounts have to change. The corrective action may require the removal of the ingredient in its totality. Manufacturing operations request a cancellation of the entire batch. The batch will be released again after the recipe is updated. Manufacturing Operations and the Raw Material Warehouse leadership talk. The result is the cancellation of the task(s) for the ingredient picking. The Raw Material Warehouse Manager/Supervisor (or Lead) has not assigned this order to be actively picked.

Solution Action Plan:

Expediency is key in this situation. As ingredient picking is not occurring, we want to keep it that way. Revisions and cancelations must happen before the warehouse actively starts picking the batch job. To do this, the Manufacturing Production team will need to communicate and work with the Warehouse leadership.

Warehouse leadership will need to perform two actions:

- Ensure ingredient picking doesn’t start

- Cancel the open picking tasks in the system

For the first part, they will need to pull the batch job from the queue of active orders. You can do this by removing the pick-slip from the stack of orders. The next step is to cancel the open tasks in EBS. If you reverse these steps you run the risk of having a warehouse worker trying to pick that work order. They will be unable to access the order to pick in EBS but will have a pick-slip instructing them to pick it. This will cause confusion and delay. If the warehouse is running in a paperless mode, simply proceed to the step of task cancellation in EBS. The raw material warehouse will need to let production operations know when the tasks have been canceled.

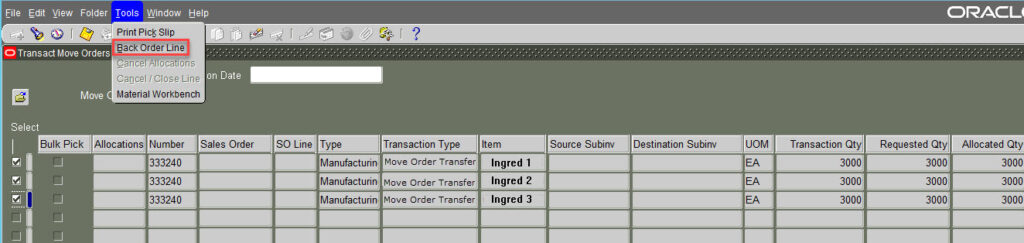

To actively cancel these tasks, query up the corresponding task in the “Transact Move Order” form. From there you can cancel the move order by selecting the function of “Back Order Line” from the Tools option.

If the Warehouse Manager/Supervisor (or Lead) has assigned the work order to be actively picked, please see the next scenario.

Batch Job Revisions

For Recipe Revisions at this phase in the process, you would follow the same steps. However, instead of canceling the Batch job, the job would be re-released once the revisions have been made.

Scenario #3 – Batch Job is Released and then Cancelled while ingredients are Picked

Scenario details:

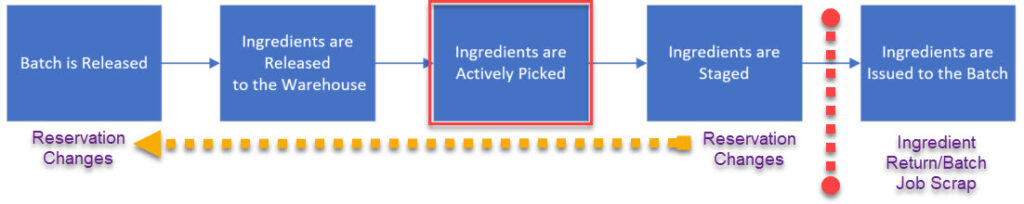

The Warehouse is actively picking the ingredients for the batch job. For some reason, the job needs to be changed. Either the equipment is down or a change in the recipe. Production operations call the Warehouse Supervisor/Manager to request that they stop picking ingredients for the batch. The Warehouse Worker is in the middle of actively picking the raw materials. This means that some of the tasks are complete. However, several tasks are still in the process of picking.

Solution Action Plan

Active picking of the order is taking place at this phase. Operations will need to stop the active picking of the order. This will require coordination with the Raw Material Warehouse leadership team. Depending on how far into the fulfillment cycle, it may take several hours before the ingredients on the batch job can be revised. The Warehouse leadership will need to evaluate where the order is in the fulfillment process. Will it be easier for the Warehouse Worker to return the material to where they found it (and reverse the execution of those picking tasks) or finish the fulfillment tasks? Once they have arrived at a decision, the leadership must communicate their intention with the warehouse staff.

Similar to Order Fulfillment; Ingredient fulfillment for batch jobs consists of two steps. They are material transfer and material issues. With batch jobs, you can revise the recipe if there are no open tasks or reservations.

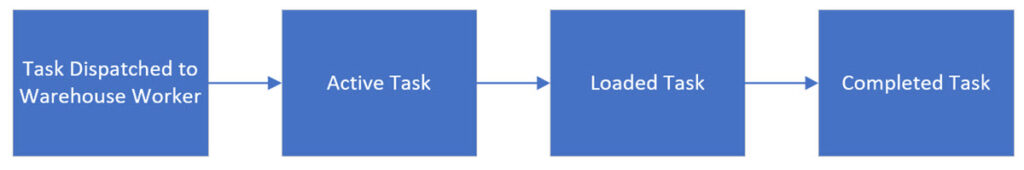

The task is in one of four states of picking. These states are as follows:

- Dispatched – Task is in the queue for action

- Active – Actively picking material

- Loaded – Transaction is in an interim state (in transit to Production)

- Completed – Production receives the material. The material is no longer in inventory because it is now on the WIP Job.

Dispatched Task

For dispatched tasks, the worker needs to abort the action. Once aborted, proceed with the steps taken in Scenario #2.

Active Task

For Active tasks, the warehouse worker needs to put the material back to where they were taking it from and abort the task in the system. Once aborted, proceed with the steps taken in Scenario #2.

Loaded Task

Loaded tasks can go one of two ways. Complete the task or abort the task. To abort the task, two events must occur in unison. First, the task needs to be undone in the system. Second, the ingredients need to be physically returned. Oracle’s Mobile Warehouse Application (MWA) refers to this action as a “Manual Unload” of the LPN. This function will tell the worker where to return the material to. Once completed, you can proceed with the steps outlined in Scenario #2.

If the revisions are not related to the picked ingredients, it might be easier to just finish the active tasks. This is done by dropping the Loaded LPN into the production area. If one or more of these items need to be returned, see the steps taken in Scenario #4.

Completed Task

For completed tasks, follow the steps outlined in scenario #4.

Scenario #4 – Recipe is adjusted after Ingredients have been Picked

Scenario details:

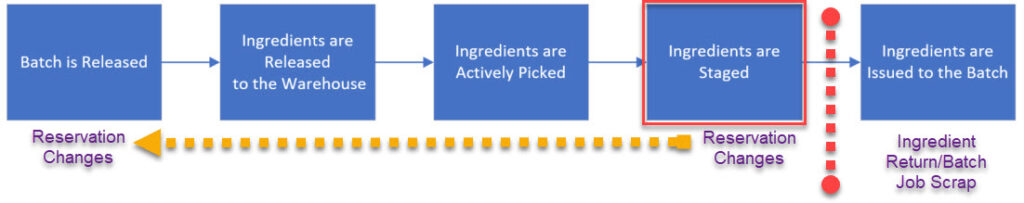

Ingredients are in the production staging area. Ingredient changes to the batch occur. This is because of corrective action in the manufacturing process. Also, the batch could have been canceled or rescheduled to be produced at a later point in time. This event could be due to an equipment failure, or a production schedule change.

Solution Action Plan:

In all of these cases, raw materials need to return to the warehouse. To remain in the production staging area would take up valuable space and cause inefficiencies in the production process. The material reservations need to be removed. Once removed, the ingredients can be returned.

To remove the material reservations, go into the Batch Job transaction and remove the reservations on the ingredients. Once this is complete, perform a directed LPN putaway and move the LPN back into the warehouse to an appropriate locator. Also, after all of the reservations have been removed you can adjust the recipe and release the batch back to the floor as necessary.

Scenario #5 – Canceling the Batch after Ingredients are Issued

Scenario details:

Batch Job has consumed the raw materials. Ingredient changes to the Batch Job occur. This is because of an equipment failure or a quality corrective change.

Solution Action Plan:

In all of these cases, raw materials need to return to inventory. However, we need to review where the batch is in the process. If ingredients have been physically issued to the batch, you’ll have to perform a scrap transaction. However, if the ingredients have not physically been issued, you can perform a return. In the scenarios where the ingredient change is to add material, an ad-hoc transaction would be the preferred action.

To perform a material return, go into the Batch Job transaction and perform a material return transaction. Receive the material back to the production staging area. The rationale behind this is to repack the materials onto an LPN. The LPN is then putaway back into the warehouse to an appropriate location.

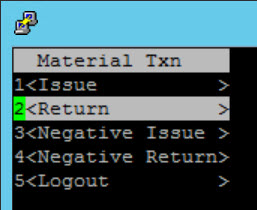

In WMS, a Batch Return can also be performed in mobile applications using the Material Txn Return function.

The return function performs two necessary things. First, it reverses the issuing of raw material components to the work order. The reversal places the materials back into inventory. These materials are also no longer reserved for the Batch Job. Ingredient changes are now possible for the work order. Second, it allows for the materials to be putaway back into stock for another job.

OPM Ingredient Changes – Conclusion

Work Order revisions for Batch Jobs will happen in a manufacturing environment. Efficiently managing these revisions is paramount. The key to achieving efficiency is to understand the process. The proper management of these changes comes with communication.

You can apply these principles to other fulfillment processes. If you are interested in learning about this process for order management, check out the Ways to easily solve Order revisions in the Oracle R12 Warehouse Management blog post. To explore applying these to discrete manufacturing check out the More ways to easily resolve material changes in Oracle R12 WIP and WMS post.

To learn more about this process or similar processes in further detail, please contact the Perficient team for more information.