Defining a Pick Path will increase efficiencies and improve your warehouse fulfillment metrics. In a physical warehouse, materials are grouped together and can be used in manufacturing or they can be finished goods that are to be shipped to a distribution center, a storefront, or directly to the consumer. To optimize the operations in a warehouse, you need to fully understand the flow of goods as they travel through your warehouse. As a part of this flow the need to develop “Pick Paths” is critical. In this blog, we will concentrate on Pick-Paths as it pertains to a warehouse worker.

What is a “Pick Path”

A Pick Path is a route a picker takes as they go through the warehouse to fulfill the tasks that they are assigned to pick and stage goods. Approximately 50% of warehouse operations are related to these tasks. There can be several different “preferred” routes depending on the needs of the order. There are different approaches. The main ones are the Optimal Wave, Zone, and Forward Picking.

The Optimal Wave for your Pick Path

An Optimal Wave model is where you start at one end of the warehouse and work your way systematically through to the other side of the warehouse. All picking tasks are complete once you have reached the other end. The optimization in this route is that all picks are sorted based on where they are within the path through the warehouse.

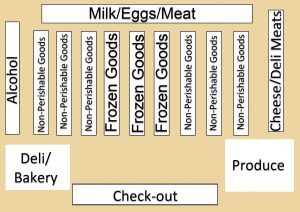

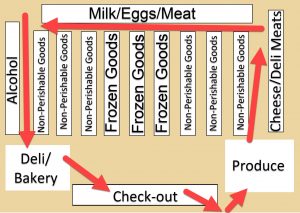

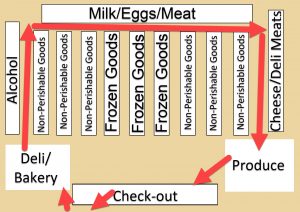

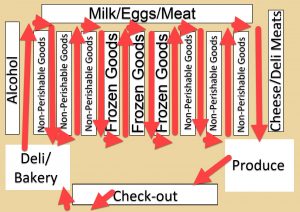

The best way to explain this would be to compare it to a trip to the Grocery Store. When you enter the grocery store, the first area you see is either the Bakery or the Produce Section (depending on the entrance). From there, if you started on the closest end wall aisle and went down each aisle until you reached the end aisle on the other side (ending in either the Produce or Bakery section; depending on where you started).

To optimally perform this trip through the store, you also need to have your shopping list properly sequenced so that you are not double-backing and revisiting aisles that you previously passed. To double-back is a waste of time and energy that could have been optimized with one single trip through each aisle. As you travel down each aisle, there’s a subset of picking as you go down each aisle, Zig-zag, or snake.

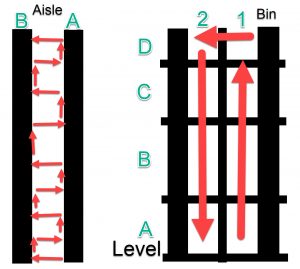

Zig-Zag

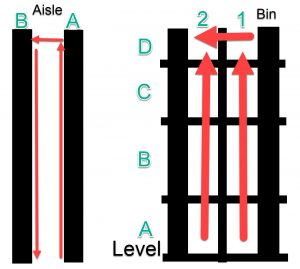

The Zig-zag Pick-Path would switch between the bins on the sides of the aisle (left-right or right-left) in a bottom-top order as the picker traverses down the aisle. For example, you would start with the bin on the bottom right and then switch to the bin on the bottom left. You would then move up one level on the left and then shift back over to the right until all levels have been checked. Once you have reached the end of the aisle, all of the items you needed would have been found and picked. This will allow you to move on to the next aisle not needing to return for this trip.

Single Rack Snake

Single Rack Snake is where you start on one side of an aisle, work your way to the end. Each Column/Bin will start with you looking at the bottom level and working your way to the top shelf. Once you reach the end, you move across the aisle and work your way down the other side. This optimizes your focus as it is on one side of the aisle at a time. In terms of energy and efficiency, it may not be as optimal as the Zig-zag approach.

Comb vs. Snake Aisle Pick Path

Pick Path – Snake Aisle

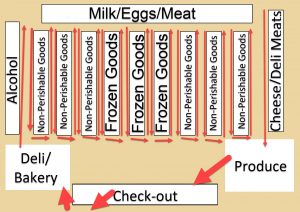

When applied to the aisle by aisle pick path, the path looks like a Snake. If applied correctly, it is a solo trip through the aisle (Up Aisle A, Down Aisle B). The path would look like a snake, but within each aisle, you’d see the Zig-Zag approach in use. The pick path goes up one side of an aisle and then down the other side of the aisle. If this path is utilizing the Single Rack Snake approach; it will look more like a comb as the entry point of each aisle be the same.

Pick Path – Comb

Both approaches have their pros and cons. You are either trading off mental focus or energy spent traversing the aisle twice. You also have to take into account how you are going to approach items on the back wall (break into sections or traverse once after the vertical aisles are complete). My recommendation would be to break it up as you travel down each aisle.

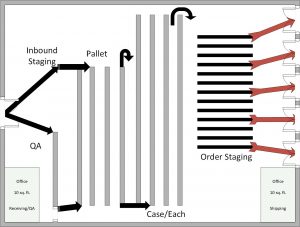

Translating Pick Paths into your Warehouse

Product Movement and Picker movements through the warehouse are Pick Paths. By streamlining and utilizing the Optimal Wave approach for pickers, you will make their time through the warehouse more efficient. Once set, the Picker will know where they need to start. They will also know when they are near the end of their current picking.

As you configure, set, and adjust your pick paths; productivity KPIs will go up. Order fulfillment will go up and throughput will go up over time. After pick paths for material picking have been set; the next step is to establish a pick path for the material flow through the warehouse. This will correspond to having material in the optimal place to be picked.

For more information on material movements, please see my blog 5 Questions to ask if you’re ready for WMS.

To change a pick path from ”snake” to ”zig zag” is that a I.t tech system change or is it a physical mechanical change?