Sophisticated Warehouse Management Solutions have been popular in Distribution Centers and Warehouses for decades. In addition to distribution centers; manufacturers have also adopted these controls to increase accuracy and achieve cost savings. Although the ideal situation would be to implement WMS; your operation may not be ready for such a robust system. So, are you prepared for WMS? Let’s ask the following 5 questions:

Prepared for WMS? – The 5 Questions

Ther 5 Questions that you should ask are as follows:

- Do you have the Infrastructure?

- Do you know how material flows?

- How large is your Warehouse?

- What is the volume of daily transactions?

- How compliant is your workforce?

Do you have the infrastructure in place?

You must look at your infrastructure and properly account for how you transact material in the warehouse. You will need to know your hardware, network access, labeling, and the organization of your processes before you can start. Examples of such infrastructure include the following:

- Network Access points in the warehouse

- Access Points/Repeaters to minimize performance issues and “dead zones”

- Mobile Devices that can access the network and transact on it (ex. RF or RFID Devices)

- Locator Grids to efficiently identify where material resides

- Barcoding for quicker and more accurate transaction recording (if not using Active RFID)

Without infrastructure in place, your WMS will be a failure before you start. For more information on some of the infrastructures and systems, please take a look at the 6 Helpful Ways to Unlock the Power out of your Warehouse Solution blog post.

Can you accurately map the flow of material through your warehouse?

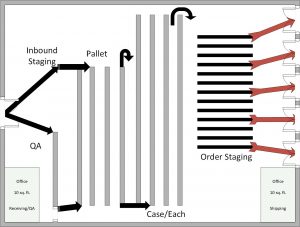

Understanding material flow through the warehouse is a key component to prepare for WMS. To prepare for WMS, you will need to explain material movement through your warehouse from inbound receipt to outbound relief. There will always be an alternate path that material will travel. The ability to map and demonstrate all of these movements will help you. These movements will be the programmed behavior of a WMS solution. This results in a reduction in training and offline processes.

Additionally, can you properly articulate the Pick Path the Warehouse workers take as they go through the warehouse? Your WMS Solution requires pick paths. Designing pick paths will increase throughput and productivity. Please see the Improve Warehouse Fulfillment with Pick Path Solutions Perficient blog for more information.

How large of a facility are we looking at?

Large warehouses are the main audience for WMS solutions. Conversely, smaller facilities can’t function with these additional rules. Remember, the solution can’t hinder productivity. If your facility is a small operation, other factors can push you towards WMS. Examples of these include the number of transactions, government regulations, and product tracking needs. The use of WMS should save and not add time to any overall process. The existing systems in smaller warehouses can be a sufficient solution.

What is the average daily volume of transactions?

The number of daily transactions can also have an impact on the necessity of a WMS solution. For example, let’s look at a facility with an average count of around 100 transactions per day. They won’t see an increase in productivity with a WMS solution. The time taken to transact is equal to their current process. If there are any savings, it’s minimal at best. As with warehouse size, there may be additional factors that would push you towards a WMS Solution. If that is the case, then transactional savings will not be one of your goals for implementation.

Workers processing boxes on a conveyor belt in a distribution warehouse is an example of a high volume of transactions

Can your workforce follow the policies and procedures that are currently in place?

To be prepared for WMS, knowledge of the published and “unpublished” warehouse processes are necessary. A WMS solution will not allow for deviations. You can build some exceptions in the system. However, constant changes to the system are not part of the design. Any lack of knowledge of these procedures will cause issues at go-live.

Warehouse workers must have the ability to do their job. Operations will stop if they can’t transact. Tricks or workarounds that have been previously used may not exist. Task execution times can increase if ignored. The ability of workers to take liberties are diminished. This is by design. The goal is to not make changes on the fly. Continual process improvement and system design are encouraged. However, there needs to be some stability in place before changes are made.

Using a digital tablet and pen to perform a physical inventory count is one feature of WMS

Conclusion – Are you Prepared for WMS?

A WMS solution is not a simple process. Use these questions as a guide to determine your readiness. The answers will have you prepared for WMS.