The use of Scheduled and Opportunistic Counting will improve your inventory controls. Cycle Counting utilizes both of these methods of counting. The utilization of both methods will increase the accuracy of your on-hand reporting. Inventory accountants need this to confidently and accurately report these numbers to investors and banks. So, what exactly is scheduled and opportunistic counting?

Before we get to that, let me remind you what a Cycle Count is. Cycle Counting is an organized division of a warehouse into manageable sections. These sections can be a range of items and/or warehouse locations. In Cycle Counting: How to effectively use – Item vs. Location, we talked about splitting up your counts by item or by location. For this blog post, I’ll be talking about what these types of counting are. I will also discuss the merits of scheduled counts versus opportunistic counts.

Scheduled and Opportunistic Cycle Counting

Scheduled Cycle Counts

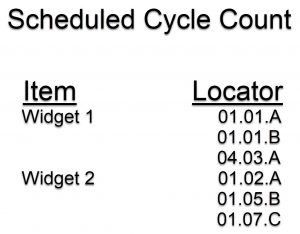

Item Based Cycle Count Scheduling

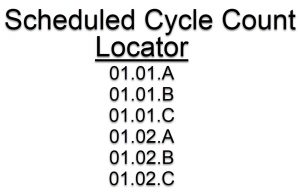

Locator Based Cycle Count Scheduling

Computer system-generated counts are Scheduled Counts. In these counts, a computerized inventory management system will generate a list of items and/or locators to count based on the parameters set forth (Value, Location, etc.). These counting tasks are directing the warehouse worker to go to a specific location and count what is there or an explicit subset of what should be residing in that location. Each count compares the system total to the amount captured in the cycle count. In cases of a discrepancy in the count, a supervisor must review the information and approve the changes.

The computer program will release counting tasks based on the schedule provided. Item-based or location-based scheduling will need to be defined. Item-based scheduling uses ABC priority calculations to plan out the schedule. Location-based scheduling uses a list of locators and dates. Either way, once created these counts are ready to be performed.

Opportunistic Cycle Counts

Warehouse manager using a tablet to effectively execute an opportunistic cycle count.

A cycle count that isn’t scheduled or generated by a computer system is called an Opportunistic count. In this case, the system is not going to direct a warehouse worker to go to a specific location. Instead, the worker is going to inform the system where they are and what they are counting. As a supervisor, you are telling a warehouse worker to go count an area and report back to you on what’s there. This is good for knowing what is residing at that particular location at that time.

Opportunistic Counts validate the information captured. Information such as the item number, locator, and quantity are the typical details. Some companies also utilize Lot/Serial Number and LPN Number to capture specific information. Any changes that are out of tolerance will ask for a supervisor’s approval to make the adjustment.

Opportunistic Counting Adjustments

Opportunistic Cycle Counts will confirm what you found, it does not tell you what has been lost. As a result, uncounted items and locations will not be changed. The computer program managing the Opportunistic Count does not know if the missed item/location count was intentional or not. The intention of the warehouse worker is unknown to the system. The worker could be only looking for the specific locations/items that they counted. Skipped locations and/or items may be counted at a later point in time. That point of time is unknown to the computer system. No negative adjustments are applied because there is no definitive logic on when these follow-up counts will occur.

Cycle counts and physical inventory counts are not executed the same way. The act of the count is the same. However, cycle counts can occur while daily operations are ongoing. There are no external inventory fluctuations to impact the on-hand count when performing a physical inventory. One thorough pass through the warehouse will suffice. Cycle counts are more like periodic spot checks to keep inventory in alignment between the governing system and physical reality.

Scheduled & Opportunistic Counting – Conclusion

As with the approach of locator-based and item-based counting; to fully optimize and gain full efficiency of your inventory controls through cycle counting will need to incorporate both scheduled and opportunistic counting. The goal here is to use both styles most efficiently. Verification that the system is accurate is an ideal reason to use Scheduled Counting. Fixing discrepancies on the spot is ideal for Opportunistic counts. In my next blog, Cycle Counts: How to inspire and make it work for growing businesses, we will go into how to use these types of cycle counts to maximize your effectiveness. We will also review a few other cycle count strategies.

So detailed and informative! Great job with this one!