Problem Statement:

Oracle Fusion Costing Distribution process will treat the Outside Processing (OSP) as ordinary items (Direct Material/Material). If you are procuring direct items to work orders or have an outside service provided in a sub-assembly as a work order step, Oracle Cost Management solution will cost the two “items” as Direct Material given the Cost Component Mappings. Also, if this is a standard costed assembly, OSP Portion will be shown as ordinary material at the standard cost definition of the item. If in the beginning OSP Items are setup as regular items then identifying and reporting on OSP work and associating different costing methods can be a challenge.

There is a way to account for OSP charges separately.

Solution/Create:

- Cost Category and define the OSP items under this Cost Category.

- A new Cost element and have a new Component Group

- A new Cost Profile and associate the newly created Component Group

- Cost Profile Defaulting Rule

Results:

This approach will provide greater flexibility on setting a different cost method to OSP items.

Ability to define actual cost for OSP Items and see their variances in manufacturing as opposed to Procurement. (If the OSP is defined as standard costed item, the variance will be seen as Price Purchase Variance, if the OSP is defined as actual costed item, then the variance will be on the Work Order. Did you know that you can define a standard cost for an item that has an Actual Costing profile!)

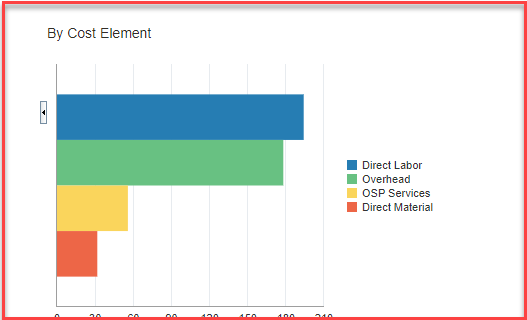

See the OSP Portion of the assembly cost as a separate cost element in Cost Rollup

Report and analyze OSP Cost in Work Order Cost separately

Contact

Contact Mehmet Erisen at Perficient for more information on how Perficient can help you implement Oracle Fusion Cloud Supply Chain Management solutions