Some call it the Fourth Industrial Revolution. We’re ushering in the age of automation technology, powered by software robots and artificial intelligence (AI).

Today robotics are everywhere from agriculture to space, collaborating and seamlessly working hand in hand with human workers. In fact, it’s estimated that 1.3 million industrial robots will arrive in factories by 2018, and the international market value for robotics is now $32 billion.

My personal favorites are the industry robots that work on assembly lines, which are capable of putting together everything from a television circuit board to a Volkswagen. (Fun fact: Tesla, the major automaker, uses 10 of the world’s largest robots in its manufacturing process, and all 10 are named after X-Men characters.)

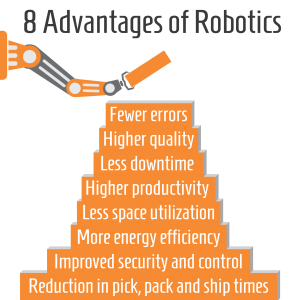

Now why are robots so important, especially in manufacturing? There are plenty of reasons.

Here’s a closer look at how robotics are impacting lives on a day-to-day basis:

- Benefits for businesses: When a product is manufactured with precision and high repeatability every time, repairs are few and far between. And since robotic mechanisms are so accurate, the amount of raw material usage can be reduced, which helps in decreasing costs related to waste.

- Benefits for healthcare: Several robots have been developed to aid with hospital staff for triage and janitorial services. Many more are in development to work both inside and outside healthcare facilities.

- Benefits for the handicapped: Mobile robotics are being used to help people with injuries or with disabilities who find it hard to navigate in many environments.

So What Are the Risks and Downsides of Robotics?

1. Resources: Robotics engineers are responsible for designing robots, maintaining them, developing new applications and conducting research to ensure robots are reaching their highest potential, which can go wrong at any cost.

2. Unemployment concerns: Some industries are replacing human workers in specific roles with robots, reducing healthcare and insurance costs, but also creating some concerns with unemployment.

3. Predefined programming: Robotics are completely programmed. In other words, robots do exactly what they are designed for, but they cannot improve the results of their jobs outside that predefined programming.

4. Rigidity: Robots cannot respond to danger (or urgent deadlines) the way humans do. Since they do not guarantee results, implementing a production plan from beginning to the end is crucial.

5. Up-front investment: The initial investment to integrate robotics into your business can be significant and heavy. Also employees will require training to interact with new robotic equipment, which normally takes time and financial output. Remember, regular maintenance needs can have a financial toll as well.

There’s no doubt: the opportunities with robotics are immense, and there’s a long list of advantages. But there are also a few downsides to keep in mind, too. And the better you understand them, the better you can tackle them.

Now is the time to get your foot in the automation door. When you’re ready to talk about what it can mean for your business, let us know.